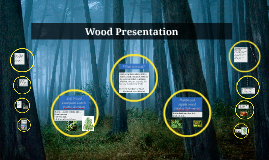

Wood Presentation

Transcript: Indigenous to Indonesia, India, and Central America, teak is a high-quality yellow to dark-brown hardwood. It’s generally straight-grained with a coarse, uneven texture and an oily feel. Teak ranges from yellow-brown to dark golden-brown in colour. Noted for its heaviness and durability, it was originally used for shipbuilding and is now often used for high-calibre outdoor furniture and decking. This is a very light-coloured medium-to-hard wood, abundant in the eastern United States. Known for its shock resistance, maple has diffused, evenly-sized pores that give the wood a fine texture and an even grain. Eastern maples are generally harder than western maples, due to the colder winters and shorter growing seasons. Both are highly durable and take any stain well. Maple can be finished to resemble walnut, cherry, or other more expensive hardwoods. Ebony (cc) photo by Franco Folini on Flickr Teak (cc) photo by Metro Centric on Flickr Pine is softwood that grows in many varieties in various parts of the world. In the U.S., Eastern White Pine, Ponderosa Pine, and Sugar Pine are some of the types used to make furniture Pine is Usually light-yellow in colour, the wood has a broadly spaced striation pattern. It’s ideal for children’s rooms, family rooms, beach cottages found primarily in northeast U.S. and Canada, beech is a heavy, pale-colored, medium-to-hard wood used widely for chairs and stools. It has a fine, tight grain and large medullar rays, similar in appearance to maple or birch woods. Beechwood has a high shock resistance and takes stains well. Peak Mahogany Research PINE (cc) photo by Metro Centric on Flickr Beech Maple Our Project Wood Types (cc) photo by jimmyharris on Flickr Beech Maple Mahogany A tropical medium-to-hard wood indigenous to South America, Central America, and Africa, mahogany’s strength makes it an excellent carving wood. It has a uniform pore structure, a medium grain, and less defined annual rings. Mahogany ranges from tan to reddish-brown in colour, and may display stripe, ribbon, rope, ripple, or blister figures. Its stability and resistance to decay makes the wood ideal for high-quality cabinetry and furniture. Brainstorm