Chemical engineering presentation

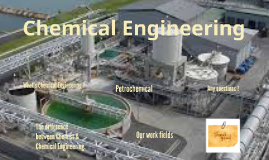

Transcript: Chemical engineering General info General Info Chemical engineering entails using math, physics, chemistry, and biology to design and improve materials, equipment, and products. By converting raw materials into useful products, these professionals can minimize costs and maximize productivity while maintaining or increasing the quality of goods and materials. It is more desingning than it is any form of hand labor but both are part part of the process. general info continued.. More info Chemical engineers work in nearly every sector, including pharmaceutical, consumer products, biotechnology, manufacturing, materials, medicine, aerospace, automotive, and fuel so that does not mean their job is a specific one. Typical duties performed in chemical engineer jobs include research and testing, designing and evaluating equipment and processes, and ensuring compliance with safety and environmental regulations. Because of the rapid advances in technology, engineers must stay informed of emerging trends in their field and industry. Some of the top industries employing chemical engineers include chemical manufacturing, architecture and engineering, scientific research, petroleum and coal product manufacturing, and the federal government General info continued ...again... just a bit more... Demand for chemical engineers’ services depends largely on demand for the products of various manufacturing industries. Many chemical engineers work in manufacturing firms that provide products to other firms. For example, environmental and sustainability concerns have led chemistry and manufacturing firms to research alternative fertilizers, resulting in a need for chemical engineers. Nearly all chemical engineers work full time. Occasionally, they may have to work additional hours to meet production targets and design standards or to troubleshoot problems with manufacturing processes. Some chemical engineers work more than 40 hours per week so the job can be very demanding Statistics of US Bureau state that the median annual wage for chemical engineers was $108,540 in May 2020 (The median wage is the wage at which half the workers in an occupation earned more than that amount and half earned less) The lowest 10 percent earned less than $68,430 (higher than the average american salary being 56,310), and the highest 10 percent earned more than $168,960 $$$ Pay General Requirements Requirements out of high school Minimum GPA: 3.academic Requirements: Many programs require four years of mathematics through differential equations and several classes in organic and physical chemistry Degree Requirements: Bachelor's degree in engineering or a physical science GRE (general records examinations) Scores: Currently, many schools are not requiring these test scores Typical Courses Transport Phenomena Advanced Thermodynamics Kinetics and Applied Math Advanced Chemical Reaction Fluid Mechanics Microhydrodynamics Steps to becoming a chemical engineer Steps To Becoming A Chemical Engineer Step 2: Earn a Bachelor's Degree in Chemical Engineering To become a chemical engineer, you need a bachelor's degree in chemical engineering. You should also consider attending a program accredited by the Accreditation Board for Engineering and Technology (ABET). This accreditation lets employers and educators know that you have received a rigorous education and meet the quality standards of the profession. This accreditation also qualifies you to pursue licensure in some states. Most chemical engineering bachelor's programs require 120-130 credits and take about four years of full-time study to complete. You'll learn about analysis and invention of chemical products and processes through classroom, laboratory, and field studies. You'll also explore how to design equipment and processes for manufacturing. Step 1: Study Chemistry, Physics, and Math in High School Chemical engineering applicants face stiff competition. As a high school student, you should start preparing early in your studies by taking classes in chemistry, biology, physics, and math. Taking college preparatory or AP courses in these areas may also increase your chances of admission, and specific coursework in trigonometry, algebra, and calculus can prepare you to meet college admission requirements. You can also benefit from extracurricular activities in science, technology, engineering, and math. Many universities and research centers offer engineering summer camps and the opportunity to perform research. Step 3 (optional): Consider a Master's Degree in Chemical Engineering While you can pursue a lucrative rewarding career as a chemical engineer with a bachelor's degree, an advanced degree paves the way to additional job opportunities. In addition to qualifying for managerial positions, a master's degree provides a deeper understanding of chemical reactions, independent research methods, and advanced laboratory skills. A career in research or academia typically requires a master's. Some schools