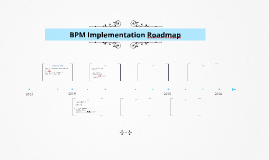

Implementation Roadmap

Transcript: Call to Action for Stakeholders Stakeholders are encouraged to actively engage in the implementation process, providing input and support at every phase. The commitment to fostering a culture of continuous improvement will significantly enhance operational performance and drive long-term success in all departments. Next Steps and Implementation Timeline Summary of Key Phases Following the conclusion of the five phases, a detailed action plan will guide the rollout of improvements across the organization. The timeline spans from initial assessments to expansion efforts, ensuring a seamless transition while tracking progress and implementing necessary adjustments at various stages. The implementation roadmap includes five critical phases: Assessment & Team Formation, Process Mapping & Prioritization, Quick Wins Implementation, System Integration & KPI Deployment, and Expansion & Continuous Improvement. Each phase lays the groundwork for a robust process development initiative, addressing operational pain points and fostering a culture of ongoing excellence. Conclusion A structured approach through key phases drives impactful process improvements and ensures sustainable success. Phase 4 – System Integration & KPI Deployment This phase focuses on standardizing procedures and establishing KPIs to drive overall process improvement and operational efficiency. Develop and Deploy KPIs Standardize Procedures To achieve consistent outcomes, all operational procedures will be standardized across production, maintenance, and quality systems. This ensures alignment in workflows and reduced variability in processes, ultimately enhancing overall performance. Key Performance Indicators (KPIs) will be tailored to measure the success of process improvements. They will include metrics such as efficiency rates, defect rates, and uptime, providing tangible data to track progress and inform decisions. Review Progress with Dashboards Monthly dashboards will be created to visually represent KPI data and overall progress. This will facilitate proactive discussions on performance reviews and help stakeholders identify areas needing attention or enhancement. Expansion & Continuous Improvement Culture This phase focuses on extending successful improvements across all operational areas, ensuring sustainability and a culture of continuous enhancement. Launch Focused Improvement Projects Build Continuous Improvement Culture Extend Improvement Activities Implement Monitoring Tools Creating a sustainable culture of continuous improvement involves training staff and recognizing their contributions. Engaging teams in regular feedback loops fosters ownership and accountability, essential for long-term success. Focused projects address chronic operational issues identified in earlier phases, yielding immediate benefits. These projects leverage existing resources and expertise to resolve specific pain points, establishing a momentum for broader change. Improvement efforts will expand to encompass Safety, Warehouse, and Utilities, promoting operational efficiency across the board. Each department will leverage lessons learned from previous phases to tackle unique challenges effectively. Simple monitoring tools such as Overall Equipment Effectiveness (OEE) metrics and downtime logs are vital for tracking improvements. These tools provide real-time data, enabling quick decision-making and adjustments during the implementation phase. Drive Long-term Excellence Long-term excellence is achieved through regular system audits and benchmarking against industry standards. Consistent evaluation ensures that improvement initiatives remain relevant and impactful. Phase 3 – Quick Wins Implementation (4–7 Months) Targeted and tactical projects during this phase lead to immediate operational improvements and enhance team collaboration. Establish Collaboration Routines Evaluate Impact of Quick Wins Structured routines for collaboration among Maintenance, Quality, and Production teams are essential. Regular communication and meetings foster a cohesive approach to challenges and ensure alignment towards shared objectives. Post-implementation analysis measures the effectiveness of quick wins, identifying areas for further improvement. Key Performance Indicators (KPIs) track success rates, and lessons learned inform future projects. Phase 1 – Assessment & Team Formation (0–2 Months) Identify Pain Points The initial phase involves setting up the core team and understanding current operations through assessments, laying the groundwork for effective process development. Key pain points and improvement opportunities are identified through collaborative brainstorming sessions and data analysis. Documenting these findings is essential for prioritizing enhancements that will drive operational efficiency and increase quality performance. Conduct Diagnostic Assessments Appoint Section Head The process begins with the appointment of a dedicated Process Development Section